Nord Lock

We are the authorized distributor for Nord-Lock Bolt Securing System in GCC. Nord-Lock is a Sweden base company and manufacturing the following Products.

A) Nord-Lock Wedge Locking Washers

Nord-Lock wedge-locking products are recognized around the world for their ability to secure bolted joints exposed to severe vibration and dynamic loads. The system cannot loosen unintentionally as it creates a wedge underneath the bolt head/nut. An ideal solution for bolted joints where failure is not an option.

In addition to Nord-Lock wedge lock washers, the range also includes steel construction washers, wheel nuts, combi bolt washers and custom solutions.

How it works

The key is the difference in angles. Since the cam angle " α " is larger than the thread pitch " β ", the pair of wedge lock washers expand more than the corresponding pitch of the thread.

Tension makes the bolt self-locking

Nord-Lock wedge-locking technology secures bolted joints with tension instead of friction. The system comprises of a pair of lock washers that has cams on one side and radial teeth on the opposite side.

Nord-Lock wedge-locking products positively lock the fastener in a joint which is subjected to extreme vibration or dynamic loads.

The Nord-Lock wedge-locking function

When the bolt and/or nut is tightened the teeth grip and seat the mating surfaces. The Nord-Lock wedge lock washer is locked in place, allowing movement only across the face of the cams. Any attempt from the bolt/nut to rotate loose is blocked by the wedge effect of the cams.

When a bolt is untightened with a wrench, the pair of washers expand more than the corresponding pitch of the thread allows the bolt/nut to rise. Nord-Lock wedge lock washers positively secure the fastener in a joint which is subjected to any kind of vibration or dynamic loads.

Tension makes the bolt self-locking

The rise of the cams between the Nord-Lock wedge lock washers is greater than the pitch of the bolt. In addition, there are radial teeth on the opposite side. The wedge lock washers are installed in pairs, cam face to cam face.

Benefits of using Nord-Lock wedge-locking solutions

- Maintains high clamp load and thereby ensures the function of the joint

- Quick and easy to install and remove with standard tools

- Locking function not affected by lubrication

- Defined and uniform friction conditions which result in a more accurate preload

- Same temperature characteristics as standard bolt / nut

- Reusable – in addition, Nord-Lock wedge lock washers do not affect the reusability of fasteners

- The washers are hardened and can support and distribute great loads

- Washers with enlarged outer diameter available for flanged bolts / nuts

- High corrosion resistance

- Can be used with fasteners up to grade 12.9 (ASTM A574)

- Reliable locking, even for joints with short clamp length

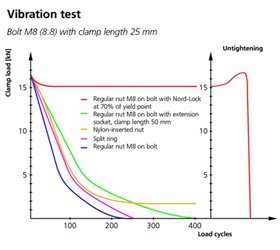

Junker test

- The Junker test, according to DIN 65151, is considered the most severe vibration test for bolted connections. During the test, the joint is exposed to transverse movements underneath the bolt head / nut, while the clamping force is continuously measured.

- Proven in Junker vibration test

Nord-Lock locking washers are proven as a safe bolt securing system according to DIN 65151 tests performed by the independent research organizations IMA and CETIM. In addition, Nord- Lock personnel performs over 10,000 live Junker vibration tests around the globe every year.

Vibration Test

The Junker test shows that Nord-Lock wedge lock washers safely secured the bolted connection; only a limited amount of tension is initially lost due to normal settlements. The wedge-locking function is verified through the clear increase in tension during untightening. All other bolt locking methods in the test failed to prevent loosening of the joint.

B) Super Bolts

Multi-jackbolt tensioners (MJTs) Bolting Made Simple.

The Nord-Lock Group manufactures patented Superbolt multi-jackbolt tensioners designed to eliminate unsafe and time consuming bolting methods. MJTs replace or retrofit existing nuts and bolts, and only require hand/air tools for installation and removal of any size tensioner.

Thousands of companies have enjoyed the benefits of using our bolting products. Switching from other bolting methods (such as hydraulic torque wrenches and stud heaters) can save you money and increase worker safety. Also, MJT's offer a better bolted connection than conventional hex nuts. Discover all the benefits below!

How MJTs work

- By tightening the jackbolts, a strong thrust (axial) force is generated. This thrust force is directed against a hardened washer. Jackbolts have a small friction diameter and can therefore create a high thrust force with relatively little torque input.

- The loads are transferred through the nut body which is positioned on the main thread by hand.

- A hardened washer is used to transfer the force while protecting the flange face.

- The thrust (axial) force of many jackbolts and the opposite reaction force of the main bolt head create a strong clamping force on the flange.

- The thrust (axial) force from the jackbolt creates an equally strong reaction force in the main bolt.

The Superbolt multi-jackbolt tensioner (MJT) takes the high preload requirements in large diameter bolting and breaks it down into manageable torques using the jackbolts threaded through the nut body. Superbolt tensioners remain easy to install, even on larger sizes, compared to standard hex nuts.

The advantage is obvious, but how exactly do our multi-jackbolt tensioners achieve this? As you can see in the animation below, the hardened washer is installed first. Then the nut body is threaded onto the existing stud or bolt, hand tight against the washer. The jackbolts are then tightened and thrust against the hardened washer. Accurate preload is achieved on the stud by torquing the jackbolts.

Our bolting technologies come in a variety of custom configurations, meeting the requirements of virtually every type of application. MJTs are available in both nut and bolt style, and we also can supply studs, expansion bolts, flexnuts, thrust collars and more. Visit our products page for more information.

Types

a) Nut-style Tensioners

Achieve high & accurate preload with only hand tools! Replaces existing nuts.

b) Bolt-style Tensioners

Achieve high & accurate preload with only hand tools! Replaces the existing bolt or stud. Requires less space than nut and stud configuration.

c) Flexnuts

For through hole applications. Ensure an equal load distribution & increase fatigue life of the bolt/stud.

d) Expansion Bolts

Replaces traditional interference or force fit bolts. Utilizes multi-jackbolt technology.

e) Pre-designed Solutions & Specials

Unique MJT designs for specific application challenges.

Our Products

Address

Vector Enterprises

1686/1,Sanaiya Street near El-Sukry Garage,

Ghala Industrial Area

Sultanate of Oman

Call Us:

+968 24592931